GROOVED GASKETS

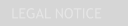

Our grooved gaskets have invariably proven their worth in all industrial sectors, also in the case of difficult sealing tasks. These are found mainly in both conventional power plants as well as in the primary circuit of nuclear power plants. On account of the good resiliency properties the grooved gaskets are ideal for applications with temperature- and pressure-change stresses. They are therefore also often referred to as composite gaskets. The sealing surface of the metal core consists of a 45° profiled sealing surface, on which a soft material layer is installed. The latter consists exclusively of high-quality materials, such as graphite or PTFE. The grooved gaskets can seal virtually all media, which is due to the selection of exclusively first-class carrier materials and sealing liner. The enormous advantage of the grooved gasket is the interplay of low minimum surface pressure and high permissible maximum surface pressure, on account of which an outstanding effectiveness can be achieved. This characteristic permits a large range of applications, this gasket is as such not only deployed for the sealing of steam, water, alkalis, organic and inorganic gases, aliphatic and aromatic hydrocarbons, alcohols, ethers, ketones, but particularly also in the case of many other chemical substances. The application temperatures are from -200 °C up to +1000 °C. In addition, the grooved gaskets can without a problem be used to reliably seal a total pressure of up to 400 bar. The grooved gaskets from our assortment can be used for all standardised flanges from DN 10 up to DN 3600. In case you need special forms, we can of course also offer tailored solutions, which are also distinguished by a high degree of quality.

Overview

The grooved gasket is one of the technical

standards, in particular in power and nuclear power

plants.

They are deployed among others as a heat exchanger

sealing, in the case of manhole covers as well as in

the case of lids for fittings in the steam cycle.

CHOOSE YOUR GASKET

Please choose the grooved gasket you need from the

selection provided below. You can access the

respective tables over the menu provided below.

SPECIFICATIONS

We deliver according to the following

standards: EN 1514-2 and works

standards suitable for flanges pursuant

to ASME B 16.20, ASME B 16.47, ANSI B

16.5 and pursuant to DIN.

PROFILES

Type KPC – grooved gasket with centring ring.

Centring ring with and without

predetermined breaking point.

Type KPC-T grooved gasket with loose

centring ring.

Type KP – grooved gasket for groove- and

spring flanges

Type KPC-B – grooved gasket with centring

ring and spherical profile

Apollon InduTec GmbH

Kurt-A.-Körber-Chaussee 73 - Halle J | 21033 Hamburg | Germany

Telefon +49 (0)40 237 67 13 - 10 | Fax +49 (0)40 361 661 53

info@apollon-indutec.de

ENGLISH

DEUTSCH

Juni 2021 | Design, Grafik, Texte, Fotos, Inhalte: plattfisch.tv brautfisch.tv